All filtration systems for pools and spas, involve the use of several pieces of equipment. One of the most important being your spa or pool filter pump. A mechanical seal is one of the key elements in the design of these pumps. The work of a mechanical seal is to prevent water leakage along the shaft of the pump.

Damage to pump seals swimming pool and spa, takes place due to overheating, vibration, and a sudden change of water pressure. There are some cases where the dirt is trapped between the seal faces. This can cause damage to the seal and causing a leak. Once you develop a leak on the pump you it does get worse, so the seal must be replaced.

Steps to replace your success seals pump shaft

Before the repair of any pool pump can begin, you must gather the necessary tools and spare parts needed to finish the job. Tools and resources include:

A pair of pliers.

A good set of ratchet.

A key small turbine.

A rubber hammer or a mall.

A set of screwdriver.

Some sand paper, emery cloth.

silicone lubricant.

A new assembly mechanical shaft seal. Make sure the correct model attached for your pump model. You can do this by consulting your owner's manual or the manufacturer of your pool pump.

A replacement joint for the pump.

Anti-Seize. To take the son of the motor shaft.

The replacement of your pump shaft mechanical seal

In general, follow all safety precautions at all meetings of any type of electrical equipment. Failure to do so may result in serious injury or death to you or others.

Before you start repairing your pump pool filter, you must disconnect all electrical power sources. Make sure you lock out and tag the main breaker. It is a further precaution, which will prevent injury to a person accidentally activating the switch.

Close the valves at the inlet and outlet access pump.To poor mechanical seal on your pool pump, you must remove the screws of four. These are the four bolts that hold the motor and mounting the wheel to the pump housing.

Hold the engine in both hands and shake from side to side slightly. This will allow you to successfully pull the engine and bracket assembly of the pump housing.

With your pliers or wrench, hold the extended end of the shaft (back end). This will prevent the shaft from moving.

Now, take your key and remove the impeller wheel of the pump shaft. If you do not have a wheel wrench handy, you can place an old cloth on the wheel and unscrew by hand. The cloth will help prevent you cut on the edges of the impeller. There is also another option, but it is a last resort. Use one of your cons wheel and tap it with your center of rubber. Always be careful not to crack or damage the turbine.

The seal plate should now be removed from the pump motor. This is done by removing four small screws holding it in place. Once the screws are removed, a free will, gently tap the seal plate engine.

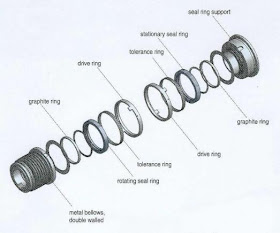

Now, before removing the mechanical seal, please be aware of how it is originally installed. This will help in the installation of the pump shaft seal.Now again use a small screw drive flat to assist in the removal of the rotating component of the seal.

The fixed part of the seal is in the recess on the seal plate located on the motor bracket. To remove, turn the plate sealing more. The fixed part of the seal is now facing down. Place the tip of a screwdriver on the back of the pad and pat.

Use an emery cloth and a little water to clean the shaft / sleeve of the motor and seal the recess in the seal plate.

Place small amount of silicone lubricant on both the drive shaft and mechanical seal in the doorway. This lubrication allows the gasket to slip up a little easier. Make sure you install the two halves of the trim in the same manner as the original. Part ceramic white trim with black rubber cup, enters the plate seal. The glass finish should be facing you.

The other part of the mechanical seal (rotating part with the spring) is on the shaft. Only after the motor bracket is bolted in place. You must use extreme care here because you do not want to damage, scratch or dirty the face of your new mechanical seal.

Check the pump seal and if it is damaged in any way, replace it. Now, if your pool pump has a joint paper (centrifugal pumps), you might want to replace it. Indeed! Each time you remove the pump, the seal of origin usually fails to close. Before installing your new pump head gasket, you must remove all traces of the old. This will ensure proper seating of the new: for example, provide a good seal.

If you must replace the head gasket of the pump, insert the new between the two halves of your pump. Now, wind your pool pump in the reverse order that you removed.

Finally, open the valves of the pump suction and discharge pipes. Restore power and boot. Check for signs of leakage. There are some cases where a paper gasket is used, a small leak may be obvious, but once the seal is wet, it will create a good seal. In some cases, one or two more turns on the bolts on the pump is necessary. However, once you follow these instructions in your repair of the pump will be a success.

Usually the manufacturers of spa and pool pumps will recommend that you repair your own pump. This is to keep your warranty and to avoid injury. However, if your warranty and you're a little short of money, I say go ahead and do your own repairs. But always, always use your trial to demonstrate safety first. Manufacturers also prefer people who are qualified to work on their products, to do so.

However, on the other hand I think the instructions right you or I can successfully replace a pump mechanical seal. Well! We'll put a lot of money and process the learning experience is priceless