Heating, Ventilation and Air-Conditioning (HVAC) Systems

The main purposes of a Heating, Ventilation, and Air-Conditioning (HVAC) system are to help maintain good indoor air quality through adequate ventilation with filtration and provide thermal comfort. HVAC systems are among the largest energy consumers in schools. The choice and design of the HVAC system can also affect many other high performance goals, including water consumption (water cooled air conditioning equipment) and acoustics (See Acoustics).

The following actions detail how engineers can design a quality system that is cost-competitive with traditional ventilation designs, while successfully providing an appropriate quantity and quality of outdoor air, lower energy costs, and easier maintenance.

Codes and Standards

The national consensus standard for outside air ventilation is ASHRAE Standard 62.1-200, Ventilation for Acceptable Indoor Air Quality and its published Addenda. This standard is often incorporated into state and local building codes, and specifies the amounts of outside air that must be provided by natural or mechanical ventilation systems to various areas of the school, including classrooms, gymnasiums, kitchens and other special use areas.

Many state codes also specify minimum energy efficiency requirements, ventilation controls, pipe and duct insulation and sealing, and system sizing, among other factors. In addition, some states and localities have established ventilation and/or other indoor air quality related requirements that must also be followed

Design in accordance with ASHRAE standards Design systems to provide outdoor air ventilation in accord with ASHRAE Standard 62.1-2007 and thermal comfort in accord with ASHRAE Standard 55–1992 (with 1995 Addenda) Thermal Environmental Conditions for Human Occupancy

Potential for Natural Ventilation and Operable Windows

In some parts of the country, where temperature and humidity levels permit, natural ventilation through operable windows can be an effective and energy-efficient way to supplement HVAC systems to provide outside air ventilation, cooling, and thermal comfort when conditions permit (e.g., temperature, humidity, outdoor air pollution levels, precipitation). Windows that open and close can enhance occupants' sense of well-being and feeling of control over their environment. They can also provide supplemental exhaust ventilation during renovation activities that may introduce pollutants into the space.

However, sealed buildings with appropriately designed and operated HVAC systems can often provide better indoor air quality than a building with operable windows. Uncontrolled ventilation with outdoor air can allow outdoor air contaminants to bypass filters, potentially disrupt the balance of the mechanical ventilation equipment, and permit the introduction of excess moisture if access is not controlled.

Strategies using natural ventilation include wind driven cross-ventilation and stack ventilation that employs the difference in air densities to provide air movement across a space. Both types of natural ventilation require careful engineering to ensure convective flows. The proper sizing and placement of openings is critical and the flow of air from entry to exit must not be obstructed (e.g., by closed perimeter rooms).

Designers should consider the use of natural ventilation and operable windows to supplement mechanical ventilation. Consider outdoor sources of pollutants (including building exhausts and vehicle traffic) and noise when determining if and where to provide operable windows.

If operable windows will be used to supplement the HVAC system, ensure that:

openings for outdoor air are located between 3-6 feet from the floor (head heigh

the windows are adjustable and can close tightly and securely;

the windows are placed to take maximum advantage of wind direction, with openings on opposite sides of the building to maximize cross-ventilation.

Selection of HVAC Equipment

In most parts of the country, climatic conditions require that outdoor air must be heated and cooled to provide acceptable thermal comfort for building occupants, requiring the addition of HVAC systems. The selection of equipment for heating, cooling and ventilating the school building is a complex design decision that must balance a great many factors, including heating and cooling needs, energy efficiency, humidity control, potential for natural ventilation, adherence to codes and standards, outdoor air quantity and quality, indoor air quality, and cost.

Where feasible, use central HVAC air handling units (AHUs) that serve multiple rooms in lieu of unit ventilators or individual heat pumps.

Although there are many different types of air handling units, for general IAQ implications in schools, air handling units can be divided into two groups: unit ventilators and individual heat pump units that serve a single room without ducts; and central air handling units that serve several rooms via duct work. Unit ventilators and heat pumps have the advantage of reduced floor space requirements, and they do not recirculate air between rooms. However, it is more difficult to assure proper maintenance of multiple units over time, and they present additional opportunities for moisture problems through the wall penetration and from drain pan and discharge problems. Central air handling units have a number of advantages as compared to unit ventilators and heat pumps serving individual rooms. They are:

Quieter, and therefore more likely to be turned on or left on by teachers and staff;

Less drafty due to multiple supplies and a return that is away from occupants;

Better at controlling humidity and condensed moisture drainage;

Easier to maintain due to reduced number of components and few units to access;

More space around units and can be accessed without interfering with class activities;

Space for higher efficiency air filters, and more surface area;

Made of heavier duty components;

Less likely to have quantity of outdoor air supply inadvertently reduced.

Specify the following features for all air handling units:

Double-sloped drain pan and drain trap depth

Double-sloped drain pan - A double-sloped pan prevents water from standing and stagnating in the pan.

Non-corroding drain pan - Made from stainless steel or plastic. Prevents corrosion that would cause water to leak inside the AHU.

Easy access doors - All access doors are hinged and use quick release latches that do not require tools to open. Easy access to filters, drain pans, and cooling coils is imperative.

Double wall cabinet - The inner wall protects the insulation from moisture and mechanical damage, increases sound dampening, and is easier to clean.

Tightly sealed cabinet - Small yet continuous air leaks in and out of the AHU cabinet can affect IAQ and energy. The greatest pressure differentials driving leaks occur at the AHU.

Double wall doors with gaskets - Double wall doors provide better thermal and acoustic insulation, and will remain flatter, allowing a better seal against door frame gaskets

Minimum 2 inch thick filter slots - For better protection of the indoor environment, as well as the equipment and ducts, the filters slots should be able to accommodate 2 in. or thicker filters.

Extended surface area filter bank - To reduce the frequency of filter maintenance and the cost of fan energy, the bank is designed to allow more filter area, such as the deep V approach or bags.

Air filter assemblies (racks & housings) designed for minimum leakage - The filter bank should have gaskets and sealants at all points where air could easily bypass the air filters, such as between the filter rack and the access door. Use properly gasketed manufacturer supplied filter rack spacers.

Air filter monitor - A differential pressure gauge to indicate the static pressure drop across the filter bank. This feature could easily be installed as an option in the field.

Corrosion resistant dampers & links - All moving parts such as pivot pins, damper actuators, and linkages are able to withstand weather and moisture-induced corrosion for the full life of the system

Energy Recovery Ventilation

Consider specifying energy recovery ventilation equipment.

Indoor air can be 2 to 5 times more polluted than outdoor air; therefore, most HVAC system designers understand that increased amounts of outdoor air supply is generally better for IAQ. Yet there are concerns over the implications that this added amount of outdoor air supply has on the first cost and operating cost of the HVAC system, as well as moisture control for the school (too wet or too dry). As a result, school designers often try to reduce the amount of outdoor air equal to – or even below -- 15 cubic feet per minute (cfm) of outside air per person, the minimum for school classrooms, as established by the American Society of Heating, Refrigerating and Air -conditioning Engineers (ASHRAE) www.ashrae.org . In many parts of the country these concerns can easily be addressed by application of basic engineering principles and off-the-shelf HVAC equipment.

First cost, energy costs, and moisture control do not have to be at odds with good IAQ. Energy recovery ventilation equipment can make the negative implications of 15 cfm per person of outdoor air behave like 5 cfm, while retaining the IAQ advantage of 15 cfm. This approach has been proven in many schools in various regions east of the Rockies, where advanced HVAC systems cost roughly the same as conventional systems, yet provide significant operating cost savings and IAQ advantages.

EPA has developed the School Advanced Ventilation Engineering Software (SAVES) package as a tool to help school designers assess the potential financial payback and indoor humidity control benefits of Energy Recovery Ventilation (ERV) systems. See also:

Overview of ERV Systems

Financial Aspects of ERV Systems

Location of Outdoor Air Intakes and Exhaust

Sloped Intake Plenum and Accessible Intake Screen

Proper location of outdoor air intakes can minimize the blockage of airflow and intake of contaminated air.

The bottom of air intakes should be at least 8 inches above horizontal surfaces (generally the ground or the roof) to prevent blockage from leaves or snow. In northern locations, more separation may be needed due to greater snow depths or drifting snow.

Intakes should not be placed within 25 feet of any potential sources of air contaminants, including sewer vents, exhaust air from the school, loading docks, bus loading areas, garbage receptacles, boiler or generator exhausts, and mist from cooling towers.

If the source is large or contains strong contaminants, or if there is a dominant wind direction in the area, the minimum separation distance may need to be increased. Air admittance valves, an inexpensive and code-approved one-way air valve, can be added to sewer vents to eliminate the potential for release of gases into the surrounding air.

Grilles protecting air intakes should be bird- and rodent-proofed to prevent perching, roosting, and nesting.

Waste from birds and other pests (e.g., rats) can disrupt proper operation of the HVAC system, promote microbial growth and cause human disease. The use of outdoor air intake grilles with vertical louvers, as opposed to horizontal louvers, will reduce the potential for roosting.

Intake Screens must be accessible for inspection and cleaning.

In existing schools, an insufficient amount of ventilation air is often the result of clogged intake screens that are inaccessible for inspection and cleaning. Screens hidden by an intake grille should be designed with a grille that is easily opened, such as a hinged grille with two quick-release latches, or in the worst case, a grille with four one-quarter turn fasteners. All screens should be easily removable for cleaning.

Consider adding a section of sloped intake plenum that causes moisture to flow to the outside or to a drain if intake grilles are not designed to completely eliminate the intake of rain or snow.

Outdoor Air Quantity

Classrooms and other school spaces must be ventilated to remove odors and other pollutants. The national consensus standard for outside air ventilation is ASHRAE Standard 62.1-2001 -

If outside air is provided through a mechanical system, then at least 15 cubic feet per minute (cfm) of outside air must be provided for each occupant. A typical classroom with 30 people requires a minimum of 15 x 30 or 450 cfm of outside air.

In spaces where the number of occupants is highly variable such as gyms, auditoriums and multipurpose spaces, demand controlled ventilation (DCV) systems can be used to vary the quantity of outside air ventilation in these spaces in response to the number of occupants. One technique for doing this is to install carbon dioxide (CO2) sensors that measure concentrations and vary the volume of outside air accordingly. If an auditorium fills up for school assembly, then CO2 concentrations will increase, a signal will be provided to the HVAC system and outside air volumes will be increased accordingly. When the spaces served by an air handler have highly variable occupancy, this type of control can both save energy and help control moisture (and mold) by reducing the quantity of humid outside air when it is not needed for ventilation. CO2 and other sensors must be periodically calibrated and maintained.

Air Filtration

In addition to "atmospheric dust," airborne particulates can include pollen, mold (fungal) spores, animal dander, insect proteins, pesticides, lead, and infectious bacteria and viruses. Designers can integrate features into the ventilation system that will provide benefits for the school occupants as well as the efficiency and longevity of the HVAC system. In addition, these features can reduce the need for expensive cleaning of the duct work and air handling units.

Filter Efficiency

Air filters should have a dust-spot rating between 35% and 80% or a Minimum Efficiency Rating Value (MERV) of between 8 and 13.

The higher the rating, the better the protection for the equipment and the occupants. It has been estimated that a 30% increase in static pressure across a coil results in a $200 per 10,000 cfm of air movement (at 7 cents per KWH). This does not include the added cost of cleaning dirty heating or cooling oils, drain pans, or air ducts. Designers should consider specifying a low efficiency (~10%) pre-filter upstream of the main filters. The pre-filters are generally easy and inexpensive to change, and will capture a significant amount of the particulate mass in the air thereby extending the useful life of the more expensive main filters.

Pressure Drop

Design more filter surface area into ventilation systems.

This has two advantages: the number of filter changes each year is reduced, thereby reducing the cost of labor to properly maintain the filters; and static pressure loss is lower, which saves money by reducing the amount of power needed to operate fans and blowers. Since different filter media are approximately proportional in their efficiency/pressure drop ratio, the most effective method for reducing pressure drop is to design more filter surface area into the filter system. This can be done by the specification of a filter with larger amounts of surface area, such as a pleated filter or bag filter. The next method is to increase the number and/or size of the filters in the airstream, for example, by mounting the filter slots in a "V" pattern, rather than a filter rack that is simply flat and perpendicular to the airstream.

Monitoring Pressure

Consider installing a simple pressure differential gauge across all filter banks.

This will prevent school facilities personnel from having to guess whether the filter is ready for replacement. A gauge with a range of zero to 1.0 in. w.g. can save money and the environment by preventing premature disposal of filters that still have useful life, and can prevent health and maintenance problems caused by overloaded filters that have blown out. The gauge should be easily visible from a standing position in an easily accessed location near the air handling unit.

Air Cleaning for Gaseous Contaminants

The most effective means of reducing exposure of occupants to gases and VOCs is to manage and control potential pollution sources. Filters are available to remove gases and volatile organic contaminants from ventilation air; however, because of cost and maintenance requirements, these systems are not generally used in normal occupancy buildings or schools. In specially designed HVAC systems, permanganate oxidizers and activated charcoal may be used for gaseous removal filters. Some manufacturers offer "partial bypass" carbon filters and carbon impregnated filters to reduce volatile organics in the ventilation air of office environments. Gaseous filters must be regularly maintained (replaced or regenerated) in order for the system to continue to operate effectively.

Ventilation Controls

Although a typical HVAC system has many controls, the control of outdoor air quantity that enters the building can have a significant impact on IAQ, yet typically is not part of standard practice. Demand controlled ventilation is addressed as a method of humidity control, but is not otherwise discussed here because its primary use is to reduce the supply of outdoor air below the recommended minimum for the purposes of saving energy, not for improving IAQ.

Outdoor Air Volume Monitoring and Control

Supplying acceptable quantities of outdoor air to occupied spaces is a critical component of good indoor air quality. Yet nearly all school ventilation systems cannot indicate whether outdoor air is even being supplied to the school, much less gauge the quantity of that air. Virtually all existing school ventilation systems rely upon a fixed damper to regulate the amount of outdoor air. Yet wind, stack effect, unbalanced supply and return fans, and constantly changing variable air volume (VAV) systems can cause significant under- or over-ventilation, which can affect IAQ and energy costs. Combinations of these effects can even cause the intake system to actually exhaust air.

Specify the addition of a measuring station that actively controls the amount of outdoor airflow by modulating the outdoor air damper and the return (recirculation) damper, if needed to overcome wind and stack effects.

These measuring stations are designed to work in limited duct space and with low air velocities. This is an easy task, as some manufacturers offer their airflow measuring stations in separate packages with dampers and actuators, and others are built into the AHU at the factory.

Moisture and Humidity Control

Uncontrolled moisture indoors can cause major damage to the building structure, as well as to furnishings and to finish materials like floors, walls, and ceilings. Uncontrolled moisture can trigger mold growth which not only damages the school facility, but can lead to health and performance problems for students and staff.

Primary causes of indoor moisture problems in new schools include:

Use of building materials that were repeatedly or deeply wetted before the building was fully enclosed

Poor control of rain and snow, resulting in roof and flashing leaks

Wet or damp construction cavities

Moisture-laden outdoor air entering the building

Condensation on cool surfaces

Controlling moisture entry into buildings and preventing condensation are critical in protecting buildings from mold and other moisture-related problems, including damage to building components.

Follow these links for more moisture information:

Building Materials

Precipitation Control

Building Envelope

Controlling Moisture in Ventilation Air

Energy Recovery Ventilators

Summer Breaks and Humidity Control

Condensation

Air Distribution and Duct Insulation

Dirt and moisture should not be present in duct systems, and must be controlled to prevent mold growth. However, it is not always possible to assure that ducts remain dirt and moisture free. In many existing schools, sheet metal ducts, as well as those constructed of or lined with insulation products, are often contaminated with mold because dirt and moisture found their way into the system.

Duct board and duct liner are widely used in duct systems because of their excellent acoustic, thermal, and condensation control properties. If the HVAC system is properly designed, fabricated, installed, operated and maintained, these duct systems pose no greater risk of mold growth than duct systems made of sheet metal or any other materials.

However, the very properties that make duct board and duct liner superior insulators (e.g., a fibrous structure with large surface area that creates insulating air pockets), also makes them capable of trapping and retaining moisture if they do get wet (though the fibers themselves do not absorb moisture).

While there is an ongoing debate about the wisdom of using insulation materials in duct systems that might retain moisture longer, all sides agree that extraordinary attention to preventing moisture contamination of the duct work should be the primary strategy for preventing mold growth. See ANSI/ASHRAE Addenda 62t and 62w, Addenda to ANSI/ASHRAE Standard 62-2001, Ventilation for Acceptable Indoor Air Quality

As a secondary strategy, designers should consider methods of reducing the potential for future problems to occur due to unforeseen moisture contamination by investigating insulation products now on the market that minimize the potential for moisture to penetrate the insulation material. These include foil vapor retarders, tightly bonded non-woven vapor retarders, butt or shiplap edges, and other techniques that have been developed by insulation manufacturers to address concerns about moisture.

Pay special attention to preventing moisture from entering duct work.

Preventing moisture from entering duct work is critical to preventing mold problems in all types of ducts. Moisture in ducts is usually due to penetration of precipitation through inlet louvers, excess moisture in outdoor air, or condensation droplets from cooling coils that are not properly drained or ducts that are not properly sealed. Under certain circumstances, when exceeding recommended maximum cooling coil face velocity, water droplets can escape cooling coils and be carried into the air stream, saturating any dirt or dust downstream. Because dust and dirt serve as a food source for mold and are usually present in all but brand new duct systems, mold will grow on any duct surface that remains wet.

If specifying duct board or internal duct lining for thermal and/or acoustical control, be sure to consider the potential for uncontrolled moisture to enter the duct over the life of the system. Select products that will minimize the potential for moisture retention in the event of unforeseen contamination of the duct system, such as those with properties that reduce the potential for moisture to penetrate the air stream surface. Ensure that all duct systems are properly fabricated and installed.

Degrease sheet metal air ducts.

The sheet steel used to make ducts has a thin petroleum or fish oil coating primarily intended to inhibit corrosion during transportation and storage of the steel. This coating may trap dirt particles, some people find the odor objectionable, and there are concerns that the emissions from the coating could affect individuals with asthma or allergies. One solution is to remove the coating from the duct using a mild cleaning agent, such as a household dishwashing liquid, in conjunction with a heated high-pressure sprayer.

Seal air ducts to prevent HVAC system air leakage

In addition to significant energy losses, air leakage from HVAC ducts and air handling units can cause significant IAQ problems due to unexpected airflow between indoors and outdoors, and between areas within the school. Air leakage from supply or return duct work contributes to the condensation of humid air in building cavities and/or on the neighboring surfaces. Air leakage can be especially problematic for ducts or AHUs that are located outside the conditioned spaces. The primary goals for the designer are to keep all air ducts within the conditioned space, and to specify that the joints and seams of all ducts, including return ducts, are sealed using an appropriate material.

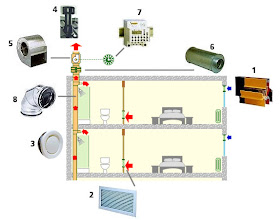

Types of Air Distribution

Nearly all schools currently use the mixed-airflow method for distribution and dilution of the air within the occupied space. Designers should investigate a method called vertical displacement ventilation or thermal displacement ventilation. This approach successfully uses natural convection forces to reduce fan energy and carefully lift air contaminants up and away from the breathing zone.

Cool supply air (blue) slowly flows out of the two heating/cooling registers in the corners of the room, and spreads across the floor. As it is warmed by people (brown columns represent students) and other warmer objects in the room, it rises upward, continuously lifting polluted air up and away from the occupants. It is then collected and exhausted outdoors.

Exhaust Air

Quick removal of concentrated air contaminants and building pressurization are two ways that exhaust systems affect IAQ. Special use areas such as science labs, vocational/technical shops, cafeterias, and indoor pools already have well established regulatory codes regarding ventilation with outdoor air and negative pressure requirements with respect to adjacent spaces. Less well recognized areas in schools where special exhaust ventilation is desirable are janitor closets, copy/work rooms and arts/crafts preparation areas where off-gasing from significant quantities of materials or products may occur. These areas should be maintained under negative pressure relative to adjacent spaces.

Provide exhaust ventilation for janitor's closets.

If housekeeping and maintenance supplies are properly stored in janitor closets, only enough air need be exhausted to place the closet under negative pressure relative to surrounding rooms. As long as air does not easily leak into or from the closet through openings such as plenums or utility chases, 10 CFM of air exhausted from the room will typically make it negative, and prevent the buildup of air pollutants.

Provide exhaust ventilation for copy/work rooms.

In addition to the code-required amount of outdoor air being supplied to this room for general ventilation, it is desirable to determine what types of equipment and activities the school plans for this room, and to supply special exhaust ventilation for concentrated pollutant sources. Two examples of sources are copy machines and work areas for adhesives. Most copier manufacturers can provide an optional vent kit, which is usually a simple plastic fitting, that allows a piece of 3" or 4" diameter flexible duct to be connected between the copier and an exhaust fan. This captures much of the heat, particles, ozone, and other pollutants and exhausts them outdoors before they can spread throughout the workroom. A small exhaust hood over a work surface, similar to a fume hood in a science lab, would also be helpful to reduce exposure when adhesives, sprays, paints, and solvents are being used in the workroom.

Provide exhaust ventilation for arts and crafts preparation areas where off-gassing from significant quantities of materials or products may occur.

Consider specifying a differential pressure monitor to monitor building pressurization.

IAQ problems are often traced to improper pressurization, which causes unexpected airflow between indoors and outdoors, and between areas within the school. To reduce introduction of unconditioned moist air and pollutants from outdoors, the building should be designed to operate between zero and 0.03 in. w.g. (0 to 7 Pa) positive, relative to outdoors.

Do not operate exhaust systems when the HVAC system is turned off to avoid bringing in unconditioned moist air that may condense on cooler indoor surfaces.

Designing for Efficient Operations and Maintenance

Ensure that all system components, including air handling units, controls, and exhaust fans are easily accessible.

To help ensure that proper operation and maintenance of HVAC system components will be performed, it is critical that the designer makes the components easily accessible. AHUs, controls, and exhaust fans should not require a ladder, the removal of ceiling tiles, or crawling to gain access. Rooftop equipment should be accessible by way of stairs and a full-sized door, not a fixed ladder and a hatch.

Label HVAC system components to facilitate operations and maintenance.

Labeling of HVAC components is an inexpensive and effective method for helping facilities personnel properly operate and maintain the HVAC systems. The labels should be easy to read when standing next to the equipment, and durable to match the life of the equipment to which they are attached. At a minimum, the following components should be labeled in each ventilation zone of the school and should correspond with the HVAC diagrams and drawings. "AHU" refers to any air handling unit that is associated with outdoor air supply.

The number or name of the AHU (e.g., AHU ##, or AHU for West Wing)

The outdoor air (OA), supply air (SA), return air (RA), and exhaust or relief air (EA) connections to the AHU, each with arrows noting proper airflow direction

The access door(s) for the air filters and the minimum filter dust-spot (or MERV) efficiency (Air Filters, minimum xx% dust spot efficiency)

The filter pressure gauge and the recommended filter change pressure (Filter Pressure, max 0.x in. w.g.)

The access door(s) for the condensate drain pan (Drain Pan)

Other pertinent access doors such as to energy recovery ventilation wheels or plates (Energy Recovery Ventilation Unit)

The minimum amount of outdoor air for each AHU (### CFM minimum during occupied times)

The outdoor air damper (OA Damper), with special marks noting when the damper is in the fully closed (Closed), fully opened (open), and minimum designed position (Min)

If a motorized relief damper is installed (EA Damper), note the same positions as above.

The access door to any outdoor air controls (OA Control(s)) such as damper position adjustments, outdoor airflow measuring stations, resets, fuses, and switches)

Breakers for exhaust fans AHU, unit ventilators

Access doors for inspection and maintenance of air ducts

Any dampers and controls for air side economizers (as appropriate)

The number or name of all exhaust fans, including the air quantity exhausted

Commissioning

Building commissioning is a quality assurance program that is intended to show that the building is constructed and performs as designed. Click here for more information on commissioning HVAC and other building systems.

Commission key building systems.

Engage a commissioning agent (the person responsible for implementing the commissioning plan) during the schematic design phase or earlier. The agent may be a member of the design team, an independent contractor, or a member of the school district staff;

Collect and review documentation on the design intent;

Make sure commissioning requirements are included in the construction documents;

Write a commissioning plan and use it throughout design and construction;

Verify installation and functional performance of systems;

Document results and develop a commissioning report.